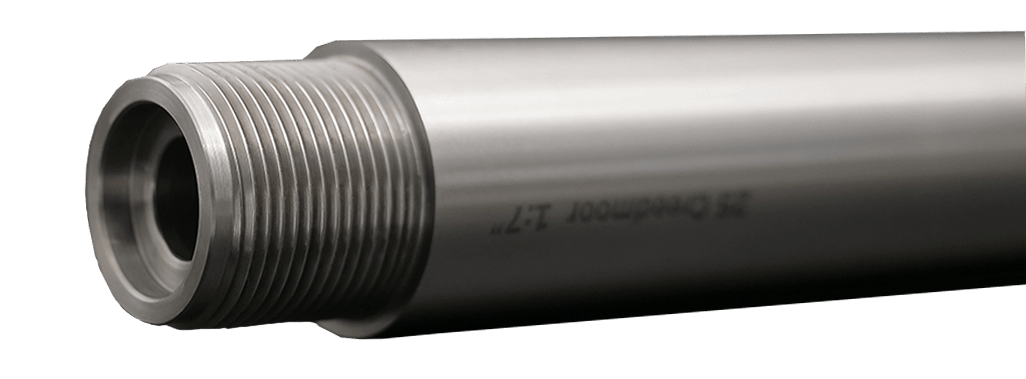

American Made Prefit Gun Barrels

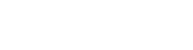

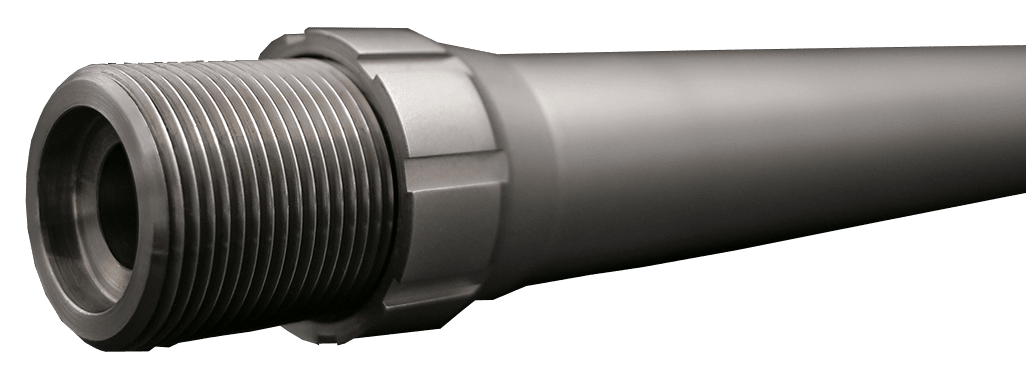

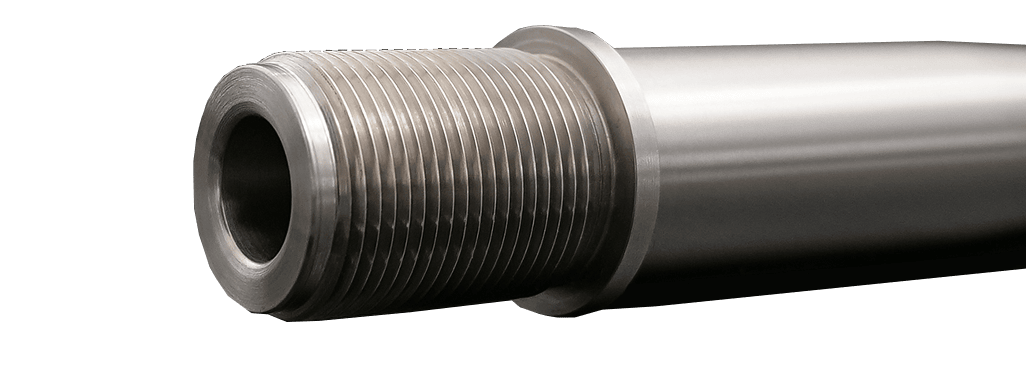

Pre Fit Gun Barrels

Welcome to Preferred Barrels prefit barrel builder home page! Here you can select your platform and options to build barrels tailored to your specs. Please read the Before You Start section to ensure you understand your responsibility in ordering a custom barrel. Take a look at our FAQ's where you can find commonly asked questions regarding prefits in general - as well as PBB specific information.

Your Premier Pre Fit Barrel

Before You Start

Your custom pre-fit barrel goes into production as soon as possible, so be sure you're ordering it correctly.

1

Select Thread Size

Please make sure to select the proper thread size to fit your action type

2

Make Certain Your Barrel & Receiver Will Work

Please do not place your order until you are fully confident that the appropriate barrel is ordered for your intended receiver

3

Changes After Submitting Are Subject to a Fee

Orders changed/canceled after 48 hours from the time submitted are subject to a revisal/cancellation fee if necessary

we strongly suggest...

Using a Qualified Individual to Install Pre-Fits

When considering a variable shoulder prefit barrel, (ones that use a torque nut opposed to integral shoulder), make sure a qualified individual who has the proper tools and gauges can perform a functional install for you, as well as hold all liability related to proper headspace

Picking the correct pre fit gun barrel

FAQ - PreFit Gun Barrels

Here are our instructions for ordering, and installing pre-fit gun barrels

Your Barrel Blanks Partner

Pre Fit Barrels Offered

Our Mission: To be the top-choice gun barrel making company for precision firearm builders

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

American Rifle Co (Nucleus, Mausingfield, Archimedes, CDG) - Fixed Shoulder - Prefit Barrels

View Product

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

Defiance Machine (Classic, Tenacity, Ruckus, anTi, and anTi X) Fixed Shoulder - 1.061"x16Px.950"

View Product

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

Falkor Defense - Fixed Shoulder - Prefit Barrels

View Product

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

Howa 1500 - Variable Shoulder - M26x1.5 (Weatherby Vanguard) - Prefit Barrels

View Product

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

- /

Mesa & Pure Precision Arms - SKLTN, SUMMIT - Fixed Shoulder Prefit Barrel

View Product