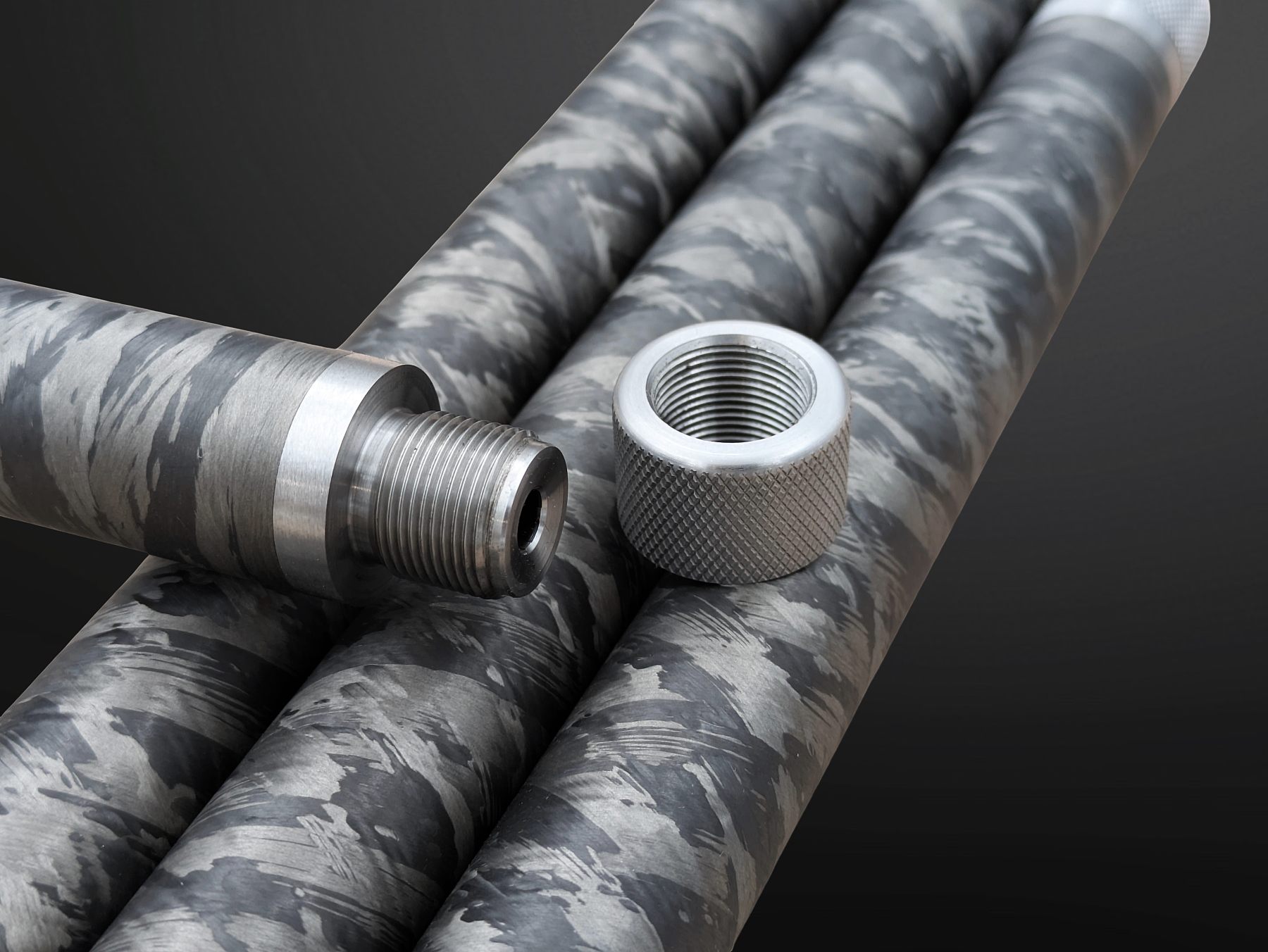

80% Carbon Fiber Barrels

Order Info

80% Carbon Fiber Barrels

Get Your Custom Carbon Fiber Barrel in ~1-2 Weeks

80% PREFIT BARREL PROCESS

Our 80% Prefit system is built around controlled production staging. We complete the rifling, hand-lapping, profiling, carbon wrap, and muzzle threading in advance — based on the most common configurations requested across today’s leading precision actions. Final chambering and finishing are then performed to your exact specifications.

This approach preserves true custom quality while dramatically reducing wait times.

Looking for something outside the listed options? Our full custom barrel builder provides expanded flexibility with traditional lead times:

https://preferredbarrelblanks.com/pre-fit-gun-barrels/

Configuration Philosophy

Every configuration in our 80% Prefit program is backed by production data.

We analyzed our most frequently built cartridges, customer-requested twist rates, and action compatibility across premium manufacturers. The selected lengths and twists reflect what consistently performs — not theoretical combinations.

Where applicable, twist rates align with SAAMI standards and modern projectile stabilization requirements, ensuring reliable performance across widely used match and hunting bullets.

At Preferred, our philosophy is simple: make true custom barrels more accessible — without making the process overwhelming. We believe precision equipment should be straightforward to configure and should ship without painful lead times. Whether you’re a professional builder with full machining capability or a shooter swapping barrels at home, our goal is the same — to help you build your perfect barrel with confidence.

FREQUENTLY ASKED QUESTIONS

Q: What actions are supported?

A:

Q: How long is the turnaround time?

A: Finished barrels typically ship in about one week — significantly faster than traditional custom-made barrels.

Q: What customization options are available?

A: Choose caliber, chamber, twist rate, length, flutes, and cerakote finish. You can also select whether you send your action in for installation or have us ship only the barrel.

Q: Can I request a different twist rate or length?

A: Yes, although with standard lead times. Click to see our custom barrel builders linked here: https://preferredbarrelblanks.com/pre-fit-gun-barrels/

Q: Are these barrels as accurate as your full custom barrels?

A: Yes. These barrels are made from the same Preferred Barrel Blanks and finished using the same tooling, processes, and quality standards as our full custom barrels — the only difference is that some machining steps are completed in advance to reduce lead time.