At Preferred Barrel Blanks, we take pride in the fact that every stage of production is done here in-house. Each aspect of the material is taken into consideration: diameter, alloy, hardness, straightness, metallurgy as far as purity and properties, and caliber to be built dimensions.

Not all steel behaves the same, so when all of the material qualities are up to spec, we order thousands of barrels worth so we have enough to work around and order perfect tooling. Another consideration is that we stress-relieve our button-rifled blanks after production. If the steel doesn’t have the proper composition, we would have devastating problems in resizing or the lack thereof.

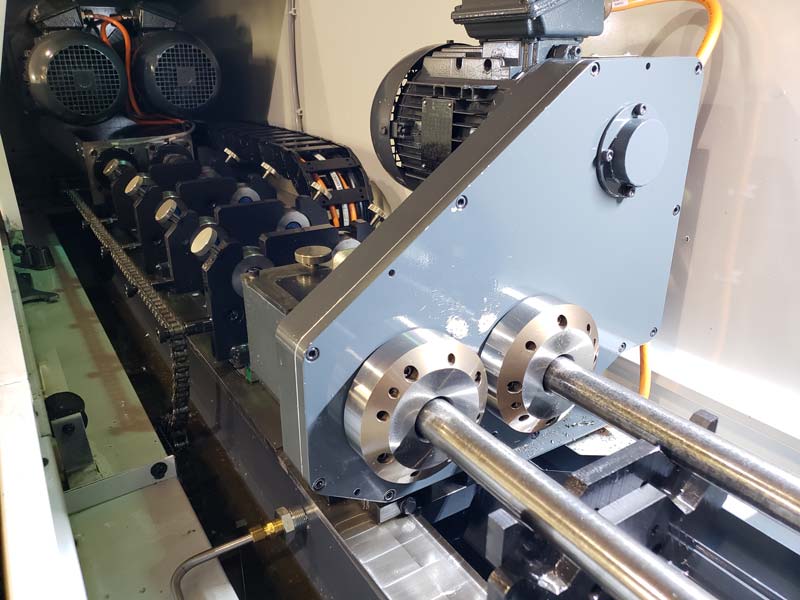

Gundrilling is a term that describes an extreme depth-to-drill diameter ratio. Typically gundrilling becomes necessary after a ratio of 10:1. Ex: 2.5” hole with a .250” drill diameter. Imagine drilling a 6.5mm barrel, which is a .250” drill bit, but your target TIR (Total Indicator Reading) muzzle drift is only .020”@28” deep.

Typically gundrilling yields .0025” TIR drift per inch, which would be .070” at the muzzle, and we are achieving .00071”/in on average for that drill diameter due to our counter-rotating workpiece technology we have in our equipment. We also sharpen all of our drills in house to not only bring the highest accuracy possible, but to be able to return that tool to work within minutes instead of weeks. You’ll notice the difference when dialing in angular/rotational misalignment before chambering/crowning, and we’re confident we will have you hooked.

Barrel blanks enable the ability to spin projectiles over 300,000 RPM and impact within virtually the same spot, if the shooter can do their part. This task is taken for granted by the normal consumer, but we dissected every variable in manufacturing aspects and we have the processes nailed down. We only trust the most valued names in premium gun barrel tool making with our orders.

Our bore/groove geometries have been meticulously engineered for maximum barrel life and yield virtually no copper fouling. With an odd number of grooves and lands, the result is a groove opposite of a land means bullet displacement can be similar, but the “pinching” effect of an even number of grooves is reduced to a minimum.